Why Choose a Wood Pellet Boiler System?

Treco has been at the forefront of biomass boiler design and installation in the UK for 20 years, having supplied over 1,000 systems nationwide we are well placed to answer this.

Wood pellet boilers provide a proven and sustainable solution for commercial heating applications.

By using compressed wood pellets made from renewable forestry by-products, these systems deliver high-efficiency, low-emission heat suitable for a wide range of properties — from schools, offices, and leisure centres to agricultural facilities and district heating networks.

- Efficiency - up to 96% efficient with automatic ignition and feed control

- Carbon-neutral - pellets are produced from sustainably managed UK and European sources

- Carbon savings - Significant CO2 savings over fossil fuels

- Stable fuel pricing - compared with fossil fuels

- Reliable and scalable – systems available from 8kW to multi-megawatt capacity

- Fully automated operation - minimal manual handling or maintenance

- Incentives for wood pellet boilers - The Boiler Upgrade Scheme for domestic and the Non-domestic Renewable Heat Incentive (RHI) for commercial and industrial

In addition to the contents of this page, we have created a blog that provides further information you can review which is titled; Wood Pellet Boilers: The Ultimate Guide.

What are wood pellets? Understanding Your Sustainable Fuel Source

Wood pellets are a highly efficient biomass fuel, distinguished by their consistent quality and high energy density. They are manufactured from compressed sawdust and wood waste, typically sourced from sawmills and the timber industry. The compression process, along with the natural lignins in the wood, gives them their characteristic compact, cylindrical shape and shiny surface.

As a renewable energy source, the carbon dioxide released during the combustion of wood pellets is absorbed by new tree growth, creating a near carbon-neutral energy cycle. This makes them a superior environmental choice compared to fossil fuels for heating.

For more detailed information on wood pellets and their sustainable sourcing, please visit our dedicated page on the website.

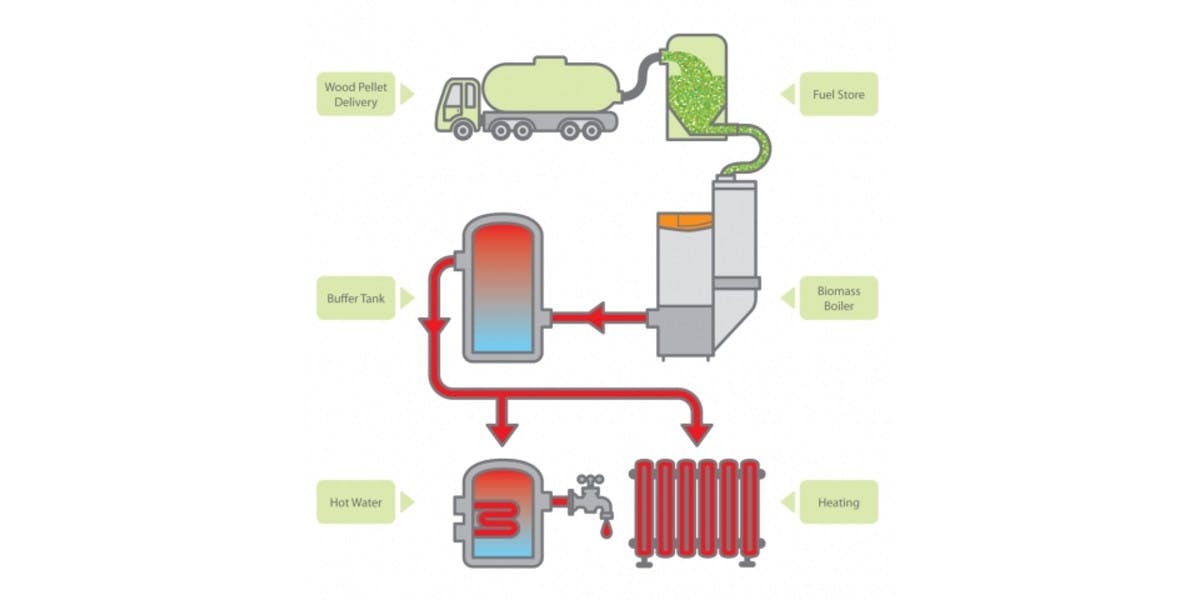

How Wood Pellet Boilers Work

Wood pellet biomass boilers are designed for fully automated operation, providing a convenience similar to that of traditional oil or gas boilers. These systems efficiently convert wood pellets into heat and hot water for properties of all sizes – from individual domestic homes to large factories and commercial complexes.

The automated process of a wood pellet boiler:

- Fuel Storage: Wood pellets are stored in an integrated hopper (for smaller systems) or a larger external fuel store/silo.

- Automated Feeding: An auger (a motorised screw) automatically draws the pellets from the store and feeds them precisely into the boiler's combustion chamber as heat is required.

- Efficient Combustion: The pellets are automatically ignited, and advanced controls regulate air supply for optimal, clean, and highly efficient burning, typically achieving efficiencies over 90%. This is significantly higher than most conventional fossil fuel systems (70-80%).

- Heat Transfer: The heat generated is transferred to water within the boiler, which then circulates through your central heating system (radiators, underfloor heating) and heats your hot water cylinder.

- Automatic Ash Removal: Modern wood pellet boilers feature automatic ash removal systems, depositing the minimal ash into a convenient tray that only requires occasional emptying.

This automation distinguishes wood pellet heating from manual log boilers, requiring significantly less day-to-day interaction from the owner.

Applications Across the UK

Treco designs and installs wood pellet heating systems for a wide range of commercial and industrial environments, including:

- Public sector buildings – schools, hospitals, local authority offices

- Agricultural and rural estates – grain drying, poultry sheds, farm complexes

- Hospitality and leisure – hotels, spas, sports facilities

- Commercial premises – manufacturing units, warehouses, business parks

- District and community heating networks

Examples of our installations in all of these sectors can be viewed on our case studies page.

We operate UK-wide, offering a complete turnkey service from feasibility and design to supply, installation, and aftercare. A breakdown of the entire process can be reviewed on the following page.

Benefits of Wood Pellet Heating for Businesses

Choosing a wood pellet boiler for your heating needs offers a compelling array of advantages for both commercial properties and industrial use across the UK:

Significant Long-Term Fuel Cost Savings:

- Predictable fuel costs - Over the past 20 years pellet process have been seen to be less volatile and typically more affordable than fossil fuels like oil and LPG, particularly for properties off the mains gas grid. This leads to substantial operational savings over the lifespan of your system. The cost of pellets can vary between suppliers and is also dependant on how many tonnes are delivered at a time. Treco are a registered BSL supplier of ENplus wood pellets, so can provide RHI accredited fuel, more details on our fuel contracts can be found here. Assuming a full load of pellets can be delivered to a site, the current cost of wood pellets in October 2025 is around £285 per tonne. At this price and a calorific value of 4.8kWh/kg this equates to a cost of 5.9p/kWh before system efficiency is factored in.

Eligibility for Incentives:

- Renewable Heat Incentive (RHI) - Commercial wood pellet biomass boilers can qualify for government or carbon-savings schemes. Since 2011 the main incentive has been the non-domestic renewable heat incentive (RHI). This is a scheme that pays the biomass boiler owner a rate for each kWh that is generated and used for eligible purposes. The system last for 20 years from installation, and typically see's a payback in 5 to 6 years of the capex. Whilst the scheme is now closed to new applicants, RHI installations can undergo changes of ownership as well as relocations to other sites, so a new owner can benefit from the RHI for the remaining term either with the second hand system or with a new biomass boiler being installed. The rates you get paid vary depending on the size of the original system and when it was installed, though it can be up to 13.62p/kWh (current rates from April 2025 to April 2026). All the current rates for April 2025 to April 2026 can be viewed here.

Exceptional Environmental Performance & Carbon Reduction:

- Reduced Emissions: Reduces carbon footprint and supports corporate responsibility targets. In terms of carbon reduction, a 100kW commercial wood pellet biomass boiler used for space heating would typically generate around 130,000kWh per annum. Based on this amount of kWh and the Carbon Trust Energy Conversion Factors, switching to wood pellets from natural gas would reduce CO2 emissions by 22,385kg per annum, switching from LPG would reduce annual CO2 emissions 26,489kg, and switching from heating oil would reduce CO2 emissions by 33,465kg per year.

Unmatched Convenience & Automation:

- Convenience - Enjoy the comfort of consistent, reliable heat with minimal manual intervention, thanks to automatic fuel feeding and ignition.

- Controls - Programmable controls allow for precise temperature management and heating schedules, mirroring the ease of conventional systems.

High Efficiency, Reliability, and Scalability:

- Efficient Combustion - With efficiencies exceeding 90%, modern wood pellet boilers convert almost all of the fuel's energy into usable heat, far surpassing typical fossil fuel systems.

- Built to high standards - These robust boilers are designed for a long operational lifespan when properly maintained, ensuring a durable heating solution for decades.

- Scalable - Systems available from 8kW to multi-megawatt capacity, and are modular so multiple boilers can be used together to achieve the required load whilst providing backup and duty assist functions. The price of an installation scales upwards exceptionally well meaning the commercial biomass boilers are priced very well per kW. As an example, the full supply and installation of a modern high quality 20kW biomass boiler and all the required ancillary items would be in the region of £20,000 whereas with a 250kW which is over 12 times larger in terms of output would be about £100,000 so only five times more expensive.

Greater Flexibility in Installation & Fuel Storage:

- Fuel flexibility - Due to their higher bulk density and calorific value, a given volume of wood pellets holds approximately 3.5 times the energy of the same volume of wood chip. This means wood pellet heating systems often require significantly smaller fuel stores than comparable wood chip systems, offering greater flexibility in equipment positioning, especially in space-constrained UK properties.

Energy Independence & Security:

- Lessen your reliance on volatile international fossil fuel markets and imported energy.

- Support the UK's renewable energy sector and local biomass supply chains.

Switching to biomass helps organisations demonstrate tangible progress toward Net Zero goals while reducing operational energy costs.

RHI payments

Fuel savings

Carbon footprint

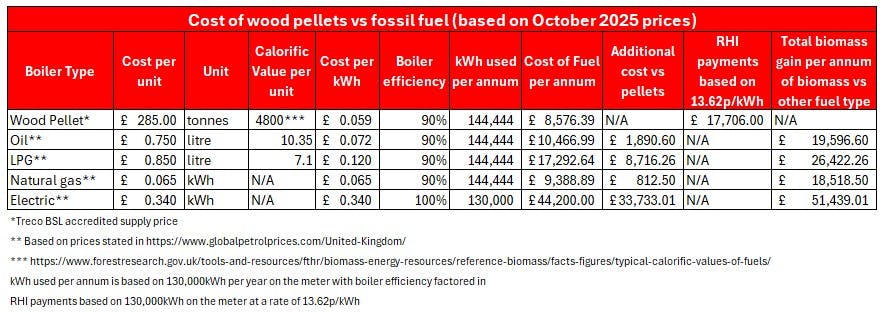

Cost of Wood Pellets vs Fossil Fuel

To demonstrate the costs of wood pellets vs fossil fuel and electric, we have put together the following table which is based on October 2025 prices. This demonstrates the cost per kWh of each fuel type so you can see how they compare, with wood pellets being the cheapest of all options.

The table runs an example based on an annual use of 130,000kWh, which is around the usage we would expect for a 100kW boiler used for space heating. This then shows what the annual fuel savings would be by switching to a wood pellet boiler, as well as the potential annual RHI payments you could benefit from. Based on the factors in the table this shows the smallest net annual gain is against natural gas at around £18,500 and the largest is against electric which would be around £51,500. Given the costs of a 100kW commercial wood pellet installation can start at around £60,000, people switching can see a payback period within a short space of time, then benefit from RHI payments for the remaining term and continued lower fuel costs in the future.

Wood Pellet Fuel Supply and Storage: Tailored to Your Site

Beyond the boiler itself, both the fuel supply and the method of transporting wood pellets from storage to the combustion chamber is a critical design element, offering varying levels of automation and flexibility. Treco are an established and accredited BSL fuel provider, supplying pellets under ENplus standard to our customers which guarantee consistent fuel quality. Treco designs and installs a range of fuel feed systems to suit different property sizes, heating demands, and site specificities.

Manual Feed Systems (Day Hopper)

- Ideal For: Typically smaller domestic properties or applications with lower heating requirements.

- How it Works: These systems feature a compact "day hopper" attached directly to the wood pellet boiler. This hopper holds enough fuel for a few days of operation, even during peak winter usage. When the fuel level drops, the hopper is manually replenished by pouring in 15kg bags of wood pellets.

- Benefits: This setup offers the smallest footprint of all fuel delivery methods, making it suitable for properties with limited space.

- Recommendation: To maximise convenience and keep fuel costs down, it's recommended to order pellets by the pallet and store them close to the boiler.

- Example Boiler: The Froling PE1 (7 to 35kW) is one of the boilers we sell and install that can utilise this option.

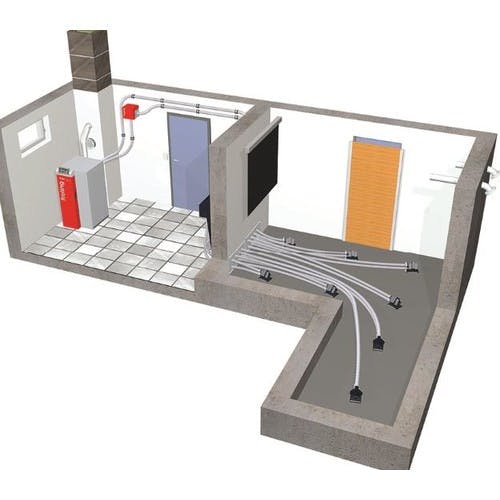

Suction Systems (Automated Bulk Feed)

- Ideal For: A wide range of properties, from larger domestic to commercial and industrial, where manual loading is impractical or undesirable.

- How it Works: This fully automated system connects your wood pellet boiler to a bulk fuel store (e.g., a dedicated silo or purpose-built fuel room). A small day hopper attached to the boiler holds a reserve of pellets. When a proximity sensor in this day hopper detects low fuel, a suction turbine automatically activates, drawing pellets from the bulk store through a suction tube until the day hopper is full.

- Benefits: Eliminates the need for manual loading, offering continuous, hands-free operation. Provides flexibility in fuel store positioning, as the suction tube can cover a considerable distance.

- Fuel Store Design: If connected to a silo, the suction tube connects directly to the base. For purpose-built fuel rooms, multiple suction cups are strategically placed along the floor to ensure pellets are drawn from a wider area.

- Example Boiler: The Froling P4 (15 to 105kW) is a popular wood pellet boiler we install that often uses this reliable suction system.

Pellet Auger Systems (Automated Bulk Feed with Physical Delivery)

- Ideal For: Medium to large commercial and industrial wood pellet heating systems where a robust and direct fuel delivery method is preferred.

- How it Works: Similar to suction systems, this method features a day hopper with a sensor and a suction turbine. However, the suction tube connects to a pellet auger positioned on the floor of the bulk fuel store. This auger runs down the centre of the store, often with sloping walls guiding pellets towards it. When the day hopper needs fuel, the auger turns, feeding pellets directly into the suction tube, which then pulls them into the day hopper.

- Benefits: Highly reliable and efficient for large volumes of pellets. The combination of an auger and suction provides consistent fuel delivery, even from large or irregular stores.

- Example Boilers: We commonly install this feed system with the Guntamatic Pro (175 to 250kW) and Biocom (50 to 100kW), as well as the Froling P4 (15 to 105kW) wood pellet boilers.

Auger & Agitator Systems (Multi-Fuel Flexibility)

- Ideal For: Larger commercial and industrial applications that require ultimate fuel flexibility, capable of handling both wood pellets and wood chips.

- How it Works: Unlike other methods, this system typically feeds directly into the boiler without a small day hopper. An auger runs straight from the boiler into the centre of the fuel store. A central hub within the store features two agitator arms that sweep across the diameter of the floor. When the boiler requires fuel, both the auger and agitator arms rotate, pushing fuel directly into the auger, which then transports it to the boiler.

- Benefits: Offers unparalleled fuel flexibility, allowing you to switch between wood pellets and wood chips based on availability or cost, providing enhanced energy security. Fully automated for large-scale operations.

- Example Boilers: We install this versatile feed system with the Guntamatic Powerchip (50 to 100kW) and Pro (175 to 250kW), as well as the Froling T4 (24 to 150kW), TX (200 to 250kW), TI (350kW), Turbomat (150 to 500kW), and Lambdamat (750 to 1,500kW) boilers.

Manual fed

Pellet silo

Pellet silo

Suction cup system

Pellet auger

Auger and agitator

Wood Pellet Boilers and Regulatory Requirements

Treco provides expert, HETAS accredited installation services for wood pellet heating systems, ensuring seamless integration with your property, whether it's a domestic dwelling, a large commercial building, or an industrial facility. Outside of the wood pellet biomass boiler selection and the mechanical and electrical design there are a number of additional considerations to ensure a system is installed in a compliant manner.

Flue Considerations

A suitable flue system or a lined chimney (designed for wood fuel) is essential for safe and efficient operation and compliance with UK Building Regulations. In addition to ensuring the flue is the correct hight to achieve the required draft, consideration in terms of the height in relation to surrounding buildings is needed to ensure correct dispersion is achieved. This is something that Local Authorities will look into as part of the planning application, and often Air Quality Assessments are required that Treco undertake in-house by utilising the DEFRA Biomass Emissions Screening Tool.

UK Regulations & Smoke Control Areas

Treco ensures all our installations comply with relevant UK Building Regulations.

For properties located in Smoke Control Areas, it is crucial to install a wood pellet boiler that has been certified as an 'exempt appliance' by DEFRA. We only supply and install compliant models, ensuring legality and peace of mind.

Planning Permission

Whilst domestic biomass boilers <45kW can come under permitted development, any boiler large than this which all commercial and industrial wood pellet boilers will be, do require planning permission. This is not just for the boiler but also the flue and any external changes that may be required for the installation of the plant. More on planning can be read in the legislation on The Town and Country Planning (General Permitted Development). Planning permission is a requirement of the RHI and this gets checked as part of the RHI application process. Given the statutory period for review is 8 weeks, we always recommend this is sought at the earliest opportunity. Treco has extensive experience in dealing with biomass boiler planning applications and can include this as part of the turnkey installation.

Environmental Permits and U4 Exemptions

When waste wood is being used as fuel there are additional regulatory pathways that need to be taken. This will not apply to the majority of those looking to have a biomass boiler as virgin wood will be the chosen fuel type. These permits are usually associated with large industrial systems that are installed in factories that produce waste wood as a by-product. Types of permits that may apply are:

- U4 Exemption -the simplest regulatory path and is specifically required when a small biomass appliance is designed to use a limited quantity of non-hazardous waste wood. This is an exemption from having a permit, and to qualify, the installation's total net rated thermal input must be less than 0.4 MW and the maximum quantity of waste burned must be less than 50 kg per hour.

- Medium Combustion Plant Permit - For boilers that over >1MW in size (input) that operate on virgin wood

- LA-PPC Part B Permit - For systems that use waste wood which is exempt from the Industrial Emissions Directive. Boilers are sized between 0.4 and 3MW with a feed rate of 50 to 1,000kg/hr.

- EPR Part A1 Permit - As per the Part B permit but for systems over 3MW in size or have a fuel feed rate of >1,000kg/hr.

- Industrial Emissions Directive (IED) Permit - The most comprehensive and stringent regulatory framework for burring waste wood.

Service, Maintenance, and Support

Beyond installation, Treco provides full after-sales support, including:

- Servicing for existing biomass boiler systems, even if not originally installed by Treco

- MCS040 HETAS accredited servicing to ensure compliance with RHI legislation

- Planned and reactive maintenance

- Breakdown support

- Remote performance monitoring

- Efficiency optimisation and emissions testing

- Supply of genuine spare parts from biomass boiler manufactures as we have direct relationships with them

We are HETAS-approved and work to the highest standards of safety and compliance.

Comply with RHI and Warranty

Reduce Breakdowns and Save Money on Parts

Increase Efficiency and Reduce Fuel Costs

Why Choose Treco for Your Wood Pellet Boiler System in the UK?

Choosing the right partner for your wood pellet heating project is paramount to its success and long-term performance. Treco stands out as a leading provider in the UK due to:

Unrivalled UK Expertise & Proven Track Record:

With 20 years of dedicated experience in the UK biomass heating sector, Treco are one of the longest standing dedicated biomass companies in the industry. With over 1,000 biomass systems sold we are the UK's leading biomass boiler installation company. Outside of the design and physical installation works, we possess in-depth knowledge of local conditions, regulations, air quality, planning and permit requirements, all crucial in ensuing you have a compliant system. Explore our successful Case Studies to see our projects in action.

Trusted UK Distributor

We act as importers and distributors for a number of the top biomass boiler manufacturers such as Guntamatic, Froling, Sommerauer, Kalvis and Effecta. In addition to this we have direct relationships with a number of others. As part of this we not only undertake manufacturer based training, but also offer training to our trade partners who purchase systems from us that they install themselves. Our direct relationships allow us to offer the most appropriate wood pellet boiler for our customers needs, at very competitive prices as we obtain them straight from source. We also have a direct line to the manufacturers we deal with for any technical support should it be required.

Trained and HETAS Accredited Professionals:

In addition to this we have HETAS accredited engineers (recognised authority for solid fuel and biomass appliances). These guarantee that our services meet the highest industry standards for quality, safety, and compliance in the UK renewable energy sector.

Comprehensive Turnkey Solutions:

We offer full turnkey biomass installation solutions. From initial consultation and custom system design to expert installation, commissioning, and ongoing maintenance, we manage every aspect of your project. We have detailed how a project progresses from initial contact to commissioning on the following page.

Proven Track Record

We have a proven track record with a vast array of clients to design, supply and install biomass systems for them as well as look after their service and maintenance requirements. This includes various NHS Trusts, nursing homes, School, University, National Trust, industrial manufacturing companies, holiday parks to name a selection.

Dedicated Aftercare & Support:

Our commitment extends beyond installation. We offer robust maintenance, servicing, and breakdown support to ensure your wood pellet boiler runs efficiently and reliably for decades. We have a team of four office staff solely dedicated to aftercare, and ten service and breakdown engineers that are accredited and registered with HETAS on the MCS040 biomass maintenance scheme. We invest in our employees, ensuring they complete manufacturer based training at factories to ensure their knowledge on the boilers they are working on is second to none. For more details, please visit our dedicated service page.

Access to Quality Fuel Advice:

Treco are a registered BSL supplier of ENplus wood pellets, so can provide RHI accredited fuel to ensure you comply with your RHI ongoing obligations, more details on our fuel contracts can be found here.

Awards, Accreditations and Compliance

Our installations

With 20 years in the industry we have a wealth of experience having installed hundreds of wood pellet boilers ourselves. In addition to this we are the sole distributors for one of the leading Austrian brands Guntamatic, and act as distributors for one of the largest Austrians biomass boiler manufacturers Froling. As part of this role we supply biomass boilers to trade, where we support them with their design and installation work.

Projects we have worked on range in size from a 15kW domestic installations, 1MW industrial boilers burning waste wood, upwards to a remote plantroom with 4MW heating capacity delivering heat to a holiday park via a 5km district heat network of underground pipe.

Below are some case studies for a selection of some of our pellet boiler installations:

Do you have a question about a commercial wood pellet boiler installation?

Speak to our experienced biomass team on 01884 250 790

01884 250790

Frequently Asked Questions (FAQs) about Wood Pellet Boilers

- What is the best wood pellet boiler?

Over the years we have installed up to 25 different manufactures so are well placed to advise on this. Whilst there may be a number of manufactures we would not look to use again, there is a wide range that we would. We have the core systems that we keep to as are distributors and purchase direct from them, but there are a number of other good manufactures out there that we would happily use like ETA, Herz, HDG. The reality is that if you had any of these top manufactures systems you would not notice the difference when they are running. The key is ensuring you do go for one of these larger top manufactures as they have the resources in place to support customers when there is an issue and can provide replacement parts quickly. Over the years we have seen smaller manufactures go under or pull out of the UK which has made it difficult for people with these systems to source parts, so when their boilers do go down they are faced with long lead times until they are back up and running.

- What size wood pellet boiler do I need?

This depends on a number of factors such as if the heat is used for space heating or process heat. Most installations whether they are domestic, commercial will be used for space heating, with process heat typically reserved for industrial sites where the heat is used for things like drying. When it comes to space heating, the boiler is sized based on the heat load of the property, this is usually based on the amount of kW needed per hour to keep a building at the required temperature when its -5C outside. This is calculated by using the size of the property as well as the thermal properties of the building fabric. This is something that we undertake at the technical site survey phase. There are however rule of thumb guidelines that can be used prior to a detailed site survey to calculate your heat load. The first is multiplying the floor area by an amount of W/m2. For a well insulated modern building you would look to use 30W/m2 and for older less well insulated buildings you would use 100W/m2 as a starting point. Another method is using your current fuel use data, if you know the kWh you use per annum you can divide this figure by 1,314 and it will provide you with an approximate load.

- How much does a wood pellet boiler cost to install in the UK in 2025?

Initial installation costs vary significantly based on the boiler's size, system complexity, and existing infrastructure. As an example, the full supply and installation of a modern high quality 20kW biomass boiler and all the required ancillary items would be in the region of £20,000 whereas with a 250kW which is over 12 times larger in terms of output would be about £100,000 so only five times more expensive. A 500kW industrial system fully supplied an installed will be int he region of £150,000 and a 1,000kW industrial system installed will be around £250,000. While a significant upfront investment, wood pellet boilers offer substantial long-term fuel savings that lead to a strong return on investment. For an accurate, tailored quote for your project, please contact us for a free site assessment.

- How much does a wood pellet boiler cost to run in the UK 2025?

As a BSL accredited fuel supplier for ENplus wood pellets, we are well placed to answer this. This does depend to a degree on the volume of fuel bought at any one time, but assuming a full load of pellets can be delivered to a site, the current cost of wood pellets in October 2025 is around £285 per tonne. At this price and a calorific value of 4.8kWh/kg this equates to a cost of 5.9p/kWh before system efficiency is factored in. In terms of annual costs you should also factor in for an annual service each year. This will vary from £500 to £750 for boilers from 50 to 250kW, £800 to £1,400 for boilers 300 to 600kW in size, and £1,500 to £2,500 for 700 to 1,500kW in size.

- How often do I need to refuel a wood pellet boiler?

This depends on your heat demand and the size of your fuel store. With automated bulk delivery systems and larger silos, refuelling can be as infrequent as a few times a year. Smaller hoppers may require more frequent topping up, as often as once a week in winter. A 100kW boiler with a 5 x 5m fuel store on a standard heating profile may only need one fill a year.

- Are wood pellet boilers noisy?

Modern wood pellet boilers are designed for quiet operation. Most noise comes from the fuel feeding mechanism, which typically operates intermittently. Many models are suitable for domestic installations without disruptive noise. Larger commercial and industrial wood pellet biomass boilers will be noisier than domestic systems, but most will operate <70dB and these are typically in remote or sperate plantrooms so noise will not be an issue.

- Can I use a wood pellet boiler in a Smoke Control Area in the UK?

Yes, you can. However, you must ensure that the specific wood pellet boiler model you choose is certified as an 'exempt appliance' by DEFRA for use in Smoke Control Areas. Treco only supplies and installs compliant models. A list of boilers classified as 'exempt appliances' can be found on DEFRAs website.

- What maintenance does a wood pellet boiler require?

Beyond occasional ash emptying (which is often automated), wood pellet boilers require annual professional servicing. Changes in the RHI legislation have meant that since April 2022 it is mandatory that anyone registered on the non-domestic RHI must have their biomass boiler serviced by a HETAS accredited company such as Treco once a year. This is an ongoing obligation of being on the RHI, and if it is not done the RHI account holders can lose RHI payments. For full details, please visit our biomass boiler servicing page.

- Are pellet boilers eligible for grants or incentives in 2025?

Yes, for domestic systems <45kW in size there is the Boiler Upgrade Scheme. This is a scheme available in England and Wales where if a house is off the gas grid, in a rural location, and chose a boiler that meets the emissions requirements, they can qualify for a £5,000 grant. The boiler upgrade scheme is not available in Scotland, instead interest free loans are available to make homes more efficient. For commercial and industrial wood pellet boilers there is the non-domestic RHI. The non-domestic RHI pays participants each quarter for every kWh of heat generated and used over the past 3 months, with the scheme lasting 20 years. Whilst the scheme is now closed to new applicants, boiler and RHI tariffs can undergo changes of ownership as well as relocations to other sites, so a new owner can benefit from the RHI for the remaining term.

- Is the RHI scheme still available for new wood pellet boiler installations in 2025?

Yes it is. The Non-Domestic Renewable Heat Incentive (RHI) scheme closed to new applications in March 2021, and the Domestic RHI closed in March 2022. While these specific schemes are no longer open to new applicants, non-domestic applications can still benefit from the RHI by acquiring an existing RHI installation that is then transferred over to the new owner. The non-domestic RHI scheme lasts for 20 years from first install, so once ownership is transferred the new owner can benefit from the remaining term that is left. This can be done using either the second hand boiler, or by having a new boiler installed on your site. The rates you get paid vary depending on the size of the original system and when it was installed, though it can be up to 13.62p/kWh (current rates from April 2025 to April 2026). All the current rates for April 2025 to April 2026 can be viewed here. We can advise on any current or emerging UK government support for renewable heating technologies.

- Can Treco service non domestic system?

Yes, our engineers maintain a wide range of commercial biomass boilers, regardless of original installer or manufacturer.

Speak to the UK’s Wood Pellet Boiler Experts

With approaching 20 years’ experience, we are one of the UK’s leading installers and developers of biomass boiler systems. Whether you’re upgrading an existing heating system or planning a new installation, Treco can design a biomass solution tailored to your requirements.

Contact our technical team to discuss your project or request a free consultation, by calling on 01884 250 790, emailing us on [email protected] or completing the enquiry form below.

Our biomass boilers

As the importers and distributors of two of the largest Austrian biomass boiler manufacturers, there's an extensive range of systems we can offer. We pride ourselves on providing the most appropriate system for your project and will source other systems if necessary. Browse through our product range or give us a call to discuss your requirements.

How to buy a biomass system

Treco will be with you at every step of the way to make sure you buy the right system for your need today and for tomorrow. It all starts with a phone call and a free site visit.

We install the entire system

We assign you a dedicated project manager who will manage a team of expert installers and oversee site works. A system design and plan will be developed to include specifications and time scales.

Treco’s RHI calculator

Try our RHI calculator to work out the fuel cost savings, potential RHI payments and payback you can expect from your biomass project. Developed in-house by us, all you have to do is enter your boiler size, installed cost, current fossil fuel usage and your preferred biomass fuel type.

After care, fuel & maintenance packages

We can help you maintain and service your system so that it is running as efficient as possible. Due to the changes in RHI tariffs we can also help you to manage your system as a business asset.

Buying, selling & moving existing biomass boilers

Due to recent changes in the RHI tariffs, an older boiler can give you a more lucrative RHI rate.