Points to consider when choosing medium to large scale biomass heating

4 minute read

Return to the article listIt's really encouraging to receive ongoing queries from clients who have been considering moving to a medium-large scale biomass which will help in the UK's course to achieve our 2020 renewable heating targets. However, there are some key considerations to take into account when moving up from smaller scale (up to 100kW) biomass boiler heating systems to the medium scale boiler systems ranging from 200kW to 1MW.

To achieve the target of 12% heat generated from renewable energy by 2020, the Department of Energy and Climate Change (DECC) estimates that 14,000 industrial and 112,000 commercial and public sector buildings would need some form of renewable heating. This means that a significant number of boilers required will be of medium scale biomass classification – 200kW to 1MW.

Moving up in scale to this size isn’t just a question of installing a bigger boiler. Whilst biomass boiler size will indeed be larger, a major consideration will be for the fuel store.

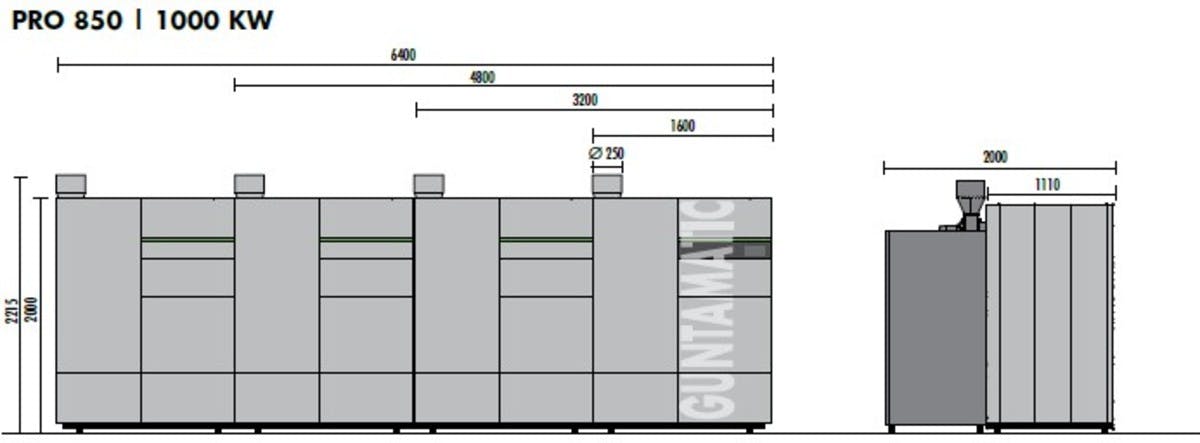

Take the new up to 1MW Guntamatic PRO boiler as an example. At 1MW, a standard heating season of 1,314 hours supplying a suitable load will require some 375 tonnes of wood chips or 270 tonnes of wood pellets a year.

Equating this to a fuel store size based on an agitator diameter of 5m requires a fuel store size of 100-125 cubic metres and a filling requirement of 12 fills a year for wood chips or six for wood pellets.

Small or under-sized fuel stores will become exhausted comparatively quickly. There is also a danger of incurring excessive costs from more frequent deliveries that can become a major limiting factor in project success.

This ‘full load’ designed space in the fuel store also needs to include sufficient reserves to ensure that the fuel supply does not run out whilst waiting for a scheduled delivery. It also prevents the store needing to be run down to a critically low volume to allow a ‘full load’ delivery to be achieved. A fuel store of the size indicated above for a 1MW installation should be able to take a full load delivery whilst high working reserve to ensure continuity of supply.

Space for the fuel store also needs to include access and adequate space for the fuel delivery vehicle and its turning circle, both of which will be of a much larger size. A tipped delivery into an underground store or from a ramp down to an above ground store at this scale may be amongst the simplest solutions. An adjacent fuel store where fuel is blown in from the delivery vehicle or via a fast auger chip as is ‘hook bin’ delivery are other workable solutions. A hook bin, with an internal walking floor, is a fuel store in its own right and becomes very efficient for a boiler of this size.

Space requirements for the boilers themselves aren’t always likely to be a major issue. If an oil boiler/s are being replaced there should already be significant oil storage capacity and room for tanker delivery vehicles to manoeuvre so the space concerns may also not be as big an issue as it first might seem.

Alongside fuel, ash handling and disposal also becomes a larger volume issue. The straightforward incorporation of auto de-ashing using a vacuum suction system into a larger wheeled bin can be a good solution to reduce time and effort spent.

The considerations of space and sizing highlighted above have focussed on a single boiler system. Larger commercial and industrial applications such as a hotels, holiday complexes or hospitals can all have significant summer heat loads.

Wood chip can reduce annual fuel costs by 50%-80% compared to oil which is a substantial saving, becoming even more significant at the higher heat output ranges. For example, the fuel cost savings using bought in wood chips at 100kW will be roughly £4,700 but can represent a massive savings of up to £47,000 at the 1MW level.

Although this is a massive cost saving for the business that gains it, as with the smaller boiler range, payback on the project when all savings including the Renewable Heat Incentive (RHI) income generated are taken into consideration could still be in the range of four to five years.

In addition, at this level, there is a further payback to consider. There is also a tax relief advantage for the next 12 months. The Annual Investment Allowance (AIA) for limited companies from January 1, 2016 is £200,000. This means that a business investing £400,000 in a biomass boiler heating system can claim up to £20,000 of tax relief per accounting year. Overall, this is a substantial return on investment, and one that is guaranteed for 20 years with the RHI.

So adding the AIA tax relief of up to £200,000, RHI payments and the fuel cost savings all together, not only results in a significant return of your investment but also makes the move up to 1MW opportunity a very attractive investment opportunity indeed!

We work hard during our initial survey and assessment of the site to provide you with not just a cost-effective solution, but also a solution that will work as efficiently and simply as possible through its whole life. With over 10 years of proven experience and in excess of 700 installation under our belt, we are able to offer you the best and most optimised solutions for your needs.

The results from moving up to medium to large scale biomass can be exponentially greater for the client and give them years of hassle-free heating and great paybacks. However the magnification effect can mean that, if you get it wrong, you really know about it! If you are planning a system up to 1MW, do get in touch and engage with us at the earliest stage of the project. We have managed over 700 successful installations and we pride ourselves on being able to help you take away some of the hassle and risk of getting it wrong. It’s what we do! Call us today or fill in the form below and we'll ring you right back. For more information on the sytems in our range you can also refer to the biomass boilers page.