How does a biomass boiler work?

Well, this blog will hopefully answer any initial questions you may have. We have a lot of additional information throughout our website, but the most useful page will will no doubt be the biomass boiler one which will provide some additional technical information as well as link you through to the different types of biomass systems available. You will also be pleased to hear that a government incentive is available called the Renewable Heat Incentive (RHI), which ultimately helps pay off the capex of the system. More information on this can be found on our RHI pages.

Biomass Fuel

The word biomass covers a whole range of biological mass. When it comes to heating, in the cast majority of cases wood is the type of biomass used as the fuel in the boilers. There are three main types used which are wood pellet, wood chip and logs, though there are some lesser used type on non-woody biomass like miscanthus and cereals.

Why use biomass instead of fossil fuel?

The integration of a biomass system is relatively simple. In most cases the systems are retro fitted and replace a fossil fuel boiler. The biomass boiler replaces the existing fossil fuel boiler, but the downstream heating system will remain the same, so there is no need to replace the radiators or whatever emitters are in place.

There are three main advantages in switching to biomass:

- Fuel savings - Heating with biomass can be a lot cheaper. Where there is an existing wood supply, you can see savings of around 80% against oil after factoring in costs for processing the wood

- Using biomass can qualify you for the governments Renewable Heat Incentive. This pays you every quarter for the heat used for 20 years. This not only pays for the initial capex, but provides a healthy return over the lifetime.

- It is considered carbon neutral as releases the same amount of CO₂ when burned as the trees have absorbed during there life. The Biomass Energy Centre sates it can cut emissions by up to 96%

How does a biomass boiler work?

How is fuel delivered?

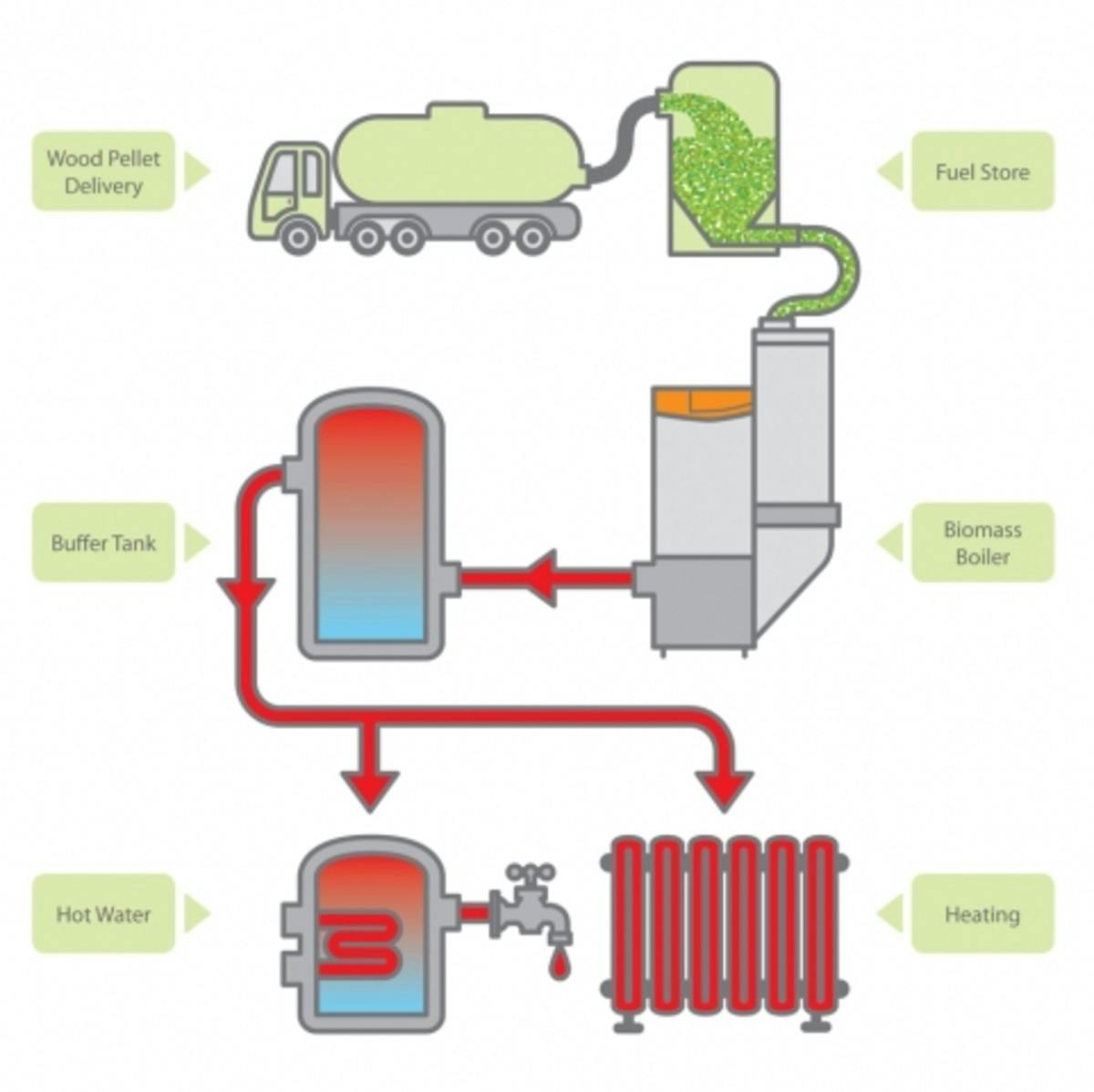

Wood pellet and chip systems are automatically fed. This means that as long as you ensure the fuel store has fuel (as you would if you had an oil or LPG tank), then the boiler takes care of the rest where it automatically takes wood from the store to the burn chamber.

With small domestic systems wood pellets are purchased in bags that the owner then pours into a small fuel store adjacent to the boiler. On larger domestic and commercial systems, wood pellets are delivered in bulk by a tanker that blow pellets into a large fuel store. Pellets are transferred from the store to the boiler either via an auger or a suction system. More information on wood pellet boilers and the range we offer can be found here.

Chip can also be delivered in a few ways. The most common method is that it is dropped off on site in bulk, then there is onsite plant that moves the chip into the fuel store via an access hatch. If there is a supply of wood on site then it can also be chipped directly into the fuel store. For people without woodland to self supply or machinery on site then you can have blown deliveries in a similar way to pellets, though this is typically more expensive. Chip is transferred from the store to the boiler using an agitator and auger. Here the agitator drags the chip into the auger, this then turns and takes fuel to the boiler. More information on wood chip boilers and the range we offer can be found here.

How do biomass boilers produce heat?

Biomass boilers use a process called gasification to produce heat. There is a two stage burn process where the fuel is initially burnt at temperatures of around 600˚C which releases gases. These gases are then re burned which allows the temperature in the burn chamber to reach around 1,200˚C. The hot gases pass through a metal heat exchanger, which then heats the water on the other side. T

Thermal stores

On the vast majority of projects thermal stores are used. These are large tanks of water (upwards of 30 litres per kW of boiler output) that act as a heat battery by storing the hot water from the boiler which is then circulated to the central heating system. The biomass boiler has temperature sensors in the thermal store, so it is responsible for keeping it at predefined temperatures. Here the boiler will automatically switch itself on when the thermal store drops below a certain temperature, then when the thermal store is up to temperature it switches itself off to conserve fuel.

Downstream Heating

The thermal store has a main system pump after it which circulates the warm water to the building(s). Each end user point will be able to send a signal back to the biomass plant room when there is a demand for heat, which results in the pump circulating the hot water. The buildings are connected to the plant room by flow and return pipework, which can be above or below the ground depending on the site, with multiple buildings connected on to the same biomass boiler, this is called district heating. Over the years we have undertaken a number of district heating schemes, such as on a 72 property housing estate (Perryfields), as well as holiday park where lodges and amenities where connected via 6km of underground heat main (Soho House). Many more can be found on our case studies page.

RHI

Heat used is recorded on heat meters. You will then submit quarterly meter readings to Ofgem who manage the RHI scheme, who then pay you for the heat used during this period. Once you are registered on the scheme you receive these payments for 20 years on the commercial scheme, and 7 years on the domestic.

We hope the above answers at least some of your questions. No doubt it will raise other ones though, so if there is anything you would like to discuss to feel free to get in touch with us.